With the development of light, small and thin characteristics in the electronic field, flexible circuit boards and rigid-flex boards have been widely used. Flexible circuit boards and rigid-flex circuit boards are the professional field of ZITROK. We have invested a lot of equipment on flexible circuit boards and rigid-flex boards, and can provide customers with various types of flexible circuit boards and rigid-flex boards. For example, single-sided flexible PCB, HDI blind hole and complex multilayer flexible PCB with embedded design, rigid-flex PCB board, etc.

The flexible circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the base material. It has the characteristics of high wiring density, light weight, thin thickness and good bendability.

Advantages Of Flex PCB Circuits

(1) Excellent flexibility

The FPC flexible circuit board can move, bend and twist freely without damaging the wires. Because it can withstand millions of times of dynamic bending, the flexible circuit can be well applied to the internal connection system of continuous movement or regular movement.

(2) Improved space utilization

In the assembly and connection of components, the conductor cross-section of the FPC board is thinner and flat compared to the use of conductive cables, which reduces the size of the conductors and can be formed along the casing, making the structure of the device more compact and reasonable, and not only can reduce the size of electronic products. The volume also reduces a lot of weight to meet the needs of the development of electronic products in the direction of high density, miniaturization and high reliability.

(3) Can provide higher assembly reliability and output Since the hardware required for internal connections is reduced, such as solder joints, relay lines, backplane lines and cables commonly used in traditional electronic packaging, flexible circuits can provide higher assembly reliability and yield. Because the traditional interconnected hardware composed of multiple complicated systems is prone to high component misalignment rate during assembly. With the advent of quality engineering, a thin flexible system is designed to be assembled in only one way, thereby eliminating the human errors usually associated with independent wiring projects.

(4) FPC flexible circuit board also has good flexibility, heat dissipation and solderability, easy assembly and connection, high wiring density, and low overall cost.

Applications Of Flex PCB Circuits

Due to the high assembly density, small size, excellent flexibility, and good thermal insulation of flexible circuit boards, flexible circuit boards are mainly used in the following aspects:

(1) Medical equipment, such as pacemakers and hearing aids.

(2) Video camera, laptop

(3) Inkjet printer

(4) Car audio

(5) Optical drive, etc.

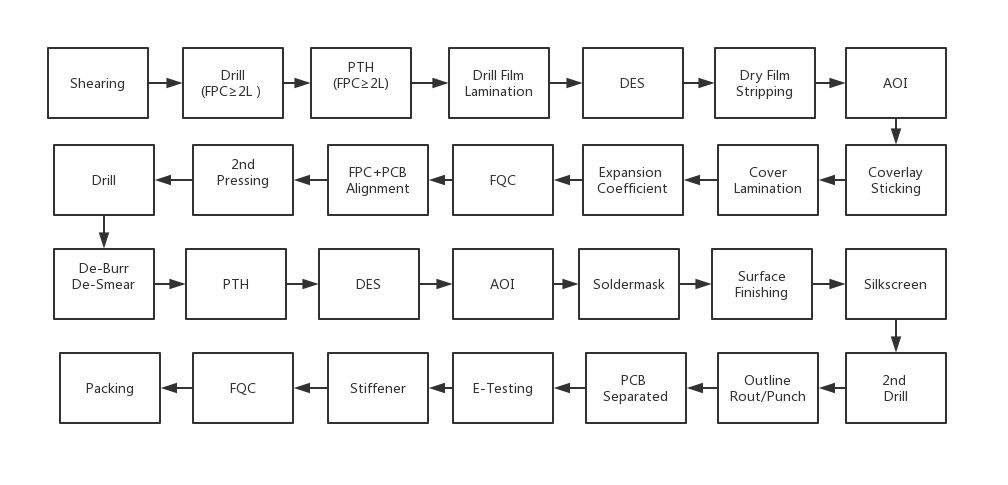

Flex PCB Circuits Manufacturing Flow

Capabilities Of Flex PCB Circuits with Zitrok

| Material |

PI, LCP, PTFE |

| Layer |

1-10 layer |

| Finished thickness |

0.1-0.8 mm |

| Finished size |

9*22 inch |

| Minimum bending radius |

3-6 times of the board thickness |

| Line Width/ Spacing |

2.5/2.5 mil |

| Appearance size precision |

±0.05 mil |

Overview Of Rigid-Flex PCB Circuits

Rigid-flex board is a combination of soft board and hard board. It is a circuit board formed by combining a thin layered flexible bottom layer and a rigid bottom layer, and then laminating it into a single component. The rigid-flex board changes the traditional flat design concept and expands to the three-dimensional concept of three-dimensional space.

Advantages Of Rigid-Flex PCB Circuits

(1) Flexibility, three-dimensional wiring, change shape according to space constraints

(2) High temperature resistance, low flame resistance

(3) Foldable without affecting the signal transmission function

(4) Prevent electrostatic interference

(5) Stable chemical changes and high reliability

(6) It is conducive to product design, can reduce errors in assembly, and improve product performance.

(7) The product volume is reduced, the weight is greatly reduced, the function is increased, and the cost is reduced.

Application Of Rigid-Flex PCB Circuits

1. Industrial use-industry, military, medical

Most industrial parts require precision, safety, and resistance to damage. Therefore, the requirements for rigid and flexible boards are: high reliability, high precision, low impedance loss, complete signal transmission quality, and durability.

2. Mobile phone-the turning point (Hinge) of the mobile phone at the folding position, the camera module (Camera Module), the button (Keypad), and the radio frequency module (RF Module), etc. The advantages of using a combination of hardware and software for mobile phones are that one is the integration of parts in the mobile phone, and the other is the consideration of signal transmission. At present, mobile phone products use soft and hard boards to replace the original combination of connectors and soft boards. Its greatest significance in the product is to increase the durability of the mobile phone folding point and the reliability of long-term use. On the other hand, due to the popularity of camera phones, coupled with the integration of multimedia and IT functions in mobile phones, the internal signal transmission volume of mobile phones is large, and the demand for modularity has also emerged.

3. Consumer electronics

4. Cars-the buttons on the steering wheel connected to the master, the car video system screen and control panel, audio, reversing radar imaging system, sensors, satellite navigation, rear seat control panel, etc.

ZITROK Capabilities Of Rigid-Flex PCB Circuits

| Layer |

2-20 |

| Minimum flexible width area |

3mm |

| Line Width/ Spacing |

inner layer 3/3mil; outer layer 3.5/3.5mil |

| Minimum Drill hole size |

0.10mm |

| Hole to conductor spacing |

Under 6 layer: 5mil;

7-11 layer: 6 mil;

12-20 layer: 8mil |

| Appearance size precision |

±0.10mm |

| Surface finishing |

ENIG, ENEPIG, HASL, FLASH GOLD, HARD GOLD, OSP |